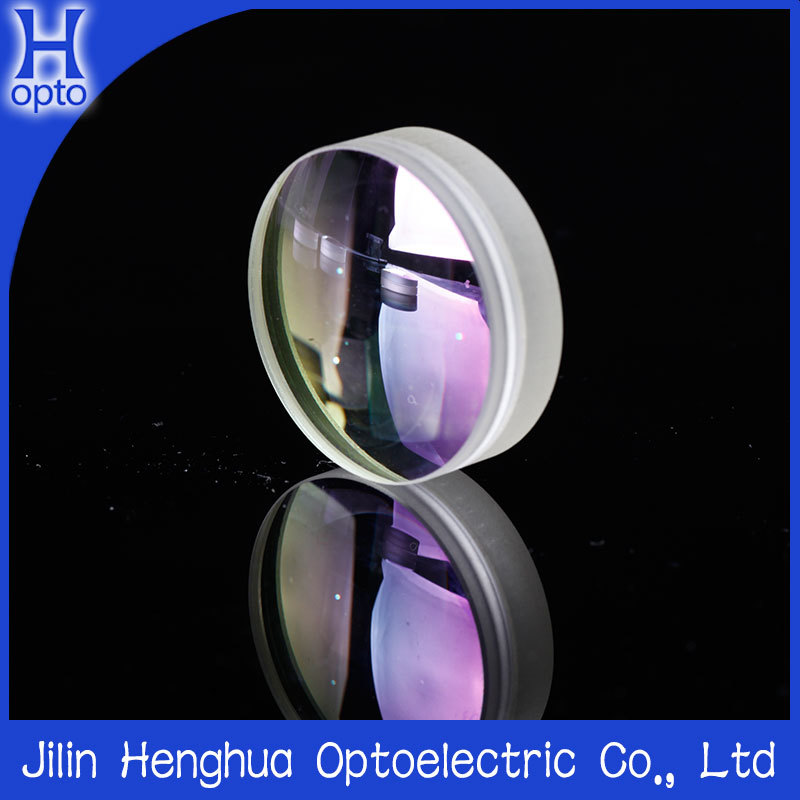

The molding process of aspheric lens on sales

Apr 13,2022

1. Precision glass molding

Precision glass molding is to heat the glass material to a high temperature to become plastic, shape it through an aspherical mold, and then gradually cool it to room temperature. Precision glass molding, not suitable for aspheric lens on sales with a diameter greater than 10mm. However, new tools, optical glasses and metrology processes are advancing the technology. Precision glass molding, although the cost is high in the early design stage (high-precision mold development), but after the mold is formed, the high-quality products produced can evenly amortize the early development costs, especially suitable for occasions requiring mass production.

2. Precision polishing and molding

Grinding and polishing are generally suitable for the occasion of producing a single aspheric lens on sales at one time, and with the improvement of technology, its precision is getting higher and higher. Significantly, the precise polishing is controlled by a computer and automatically adjusted to achieve parameter optimization. If higher quality polishing is required, magnetorheological polishing will be used. Magnetorheological polishing has higher performance and shorter time than standard polishing. Precision polishing and molding requires specialized equipment and is the first choice for sample making and small batches.

3. Hybrid molding

Hybrid molding, with a spherical lens as the base, die-casting on the surface of the spherical lens through an aspheric mold, and curing the aspheric body with a layer of high molecular polymer by ultraviolet light. Hybrid molding generally uses an achromatic spherical lens as the base, and a layer of aspherical surface is die-cast on the surface to eliminate chromatic aberration and spherical aberration at the same time. It is the manufacturing process of hybrid molding aspheric lens on sales. Hybrid molding aspheric lens on sales, suitable for high-volume manufacturing occasions that require additional features (eliminate chromatic aberration and spherical aberration at the same time).

Contact Information

Add: 177 Changda Road, Changchun Hi-Tech Industrial Development Zone, Jilin Province

Tel:+ 86-0431-89652325

Email:admin@hhoptec.com

Follow us

Mobile official website

Online Consultation

Leave your phone number and we will contact you as soon as possible

Optical manufacturers have zinc selenide lens wholesale and calcium fluoride lens sales, are very cost-effective, welcome to consult

TEL:+86-0431-89652325 TEL:18628790356 TEL:13039008691 TEL:18946792389

Company address: 177 Changda Road, High-tech Industrial Development Zone, Changchun City, Jilin Province

Email: admin@hhoptec.com

We will give you timely feedback